主要技术参数 main technical parameters:

型号 Model | 主轴直径/键槽Horizontal shaft Dia/keyway | 竖轴直径 Vertical shaft Dia | 制管范围 Pipe Range(mm) | 壁厚 wall thickness(mm) | 电机功 Motor Powe | 制管速度 Speed of Pipe/Tube |

| GZG40X | Φ40/c8 | Φ30 | Φ6-Φ31.8 | 0.3-1.5 | 5.5KW*3 | 1.0-5.0m/in |

| GZG40 | Φ40/c8 | Φ30 | Φ12.7-Φ50.8 | 0.8-3.0 | 7.5KW*3 | 1.0-5.0m/min |

| GZG50 | Φ50/c10 | Φ35 | Φ25.4-Φ76.2 | 0.8-4.0 | 11KW*3 | 1.0-4.0m/min |

| GZG60 | Φ60/c12 | Φ40 | Φ63.5-Φ89 | 1.0-5.0 | 15KW*3 | 1.0-3.0m/min |

| GZG70 | Φ70/c14 | Φ45 | Φ114-Φ168 | 1.0-6.0 | 18.5KW*3 | 1.0-2.5m/min |

| GZG80 | Φ80/c1 | Φ50 | Φ133-Φ219 | 1.5-7.0 | 22KW*3 | 1.0-2.0m/min |

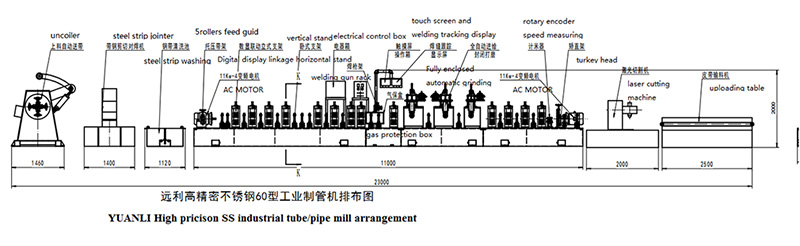

制管线用途application of stainless steel water Welded Pipe/Tube Mill:

该制管线主要用于生产各种高性能不锈钢工业焊管,在化工、核电、航空等许多工业生产中占有重要地位。

The Tube/pipe mill is mainly used to produce all kinds of high performance stainless steel welded pipes in industry, which occupies an important position in many industries such as chemical industry, nuclear power industry and aviation industry。

设备主要特点Main features of pipe/tube mill:

1. 立式支架采用双联双动结构并配显示器,可保持水平辊上下轴的平行精度,利于调模更直观更便利。

The horizontal stands adopts the double dynamic structure and display, which can maintain the parallel precision of the upper and lower axes of the horizontal roller, which is convenient to change and adjust roller sets.

2. 所有铸件采用QT-50球墨铸铁,钢性好变形小,利于提高产品的机械性能和型位公差使制管更稳定。

All castings are made of qt-50 ductile iron, which has good rigidity and small deformation, which is conducive to improving the mechanical properties and type tolerance of the products and making the pipe more stable.

3. 整机使用三个伺服电机驱动,便于整平时换芯棒,调试时节省钢带,提高成品率。伺服电机运转稳定、制动性能好。

The whole machine is driven by three servo motors, which is convenient for changing mandrel, saving steel belt and improving yield.Servo motor running stability with good braking performance.

4. 配内外焊接保护盒,密封效果好,焊缝质量高。

Equipped with internal and external welding protection box, good sealing effect and high weld quality

5. 配在线焊缝视觉跟踪系统,该智能自动跟踪系统用于不锈钢焊管焊缝偏移时,实现自动跟踪与矫正,从而实现无人值守时获得高质量的焊接效果。

Equipped with online welding seam visual tracking system, the intelligent automatic tracking system is used to realize automatic tracking and correction when stainless steel welded pipe seam is offset, so as to achieve high quality welding effect when unattended.

6. 采用先进的PLC控制系统 ,可实现高效率自动化精密生产,切管误差可严格控制在±1mm以内。

adopts advanced PLC control system, which can realize high efficiency automatic precision production, and the cutting error can be strictly controlled plus or minus1mm.

服务范围:

● 为客户提供合理的投资方案, 筛选合适的机型推荐给客户.

● 免费提供客户工厂设备规划图.

● 免费提供安装所需的基础图.

● 提供设备的安装,调试.

● 提供专业的技术培训,尽快能让买方操作人员掌握好设备的操作和使用.

![[远利精工]郴州市远利机械设备制造有限公司 [远利精工]郴州市远利机械设备制造有限公司](/template/default/index/images/en-us.png) English

English ![[远利精工]郴州市远利机械设备制造有限公司](/template/default/index/images/logo.png)

当前位置:

当前位置:

![[远利精工]郴州市远利机械设备制造有限公司 [远利精工]郴州市远利机械设备制造有限公司](/template/default/index/images/footer_logo.png)